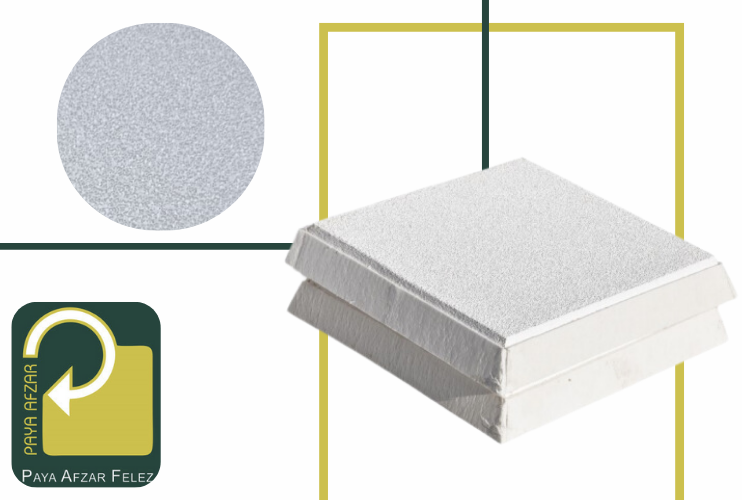

Ceramic Foam Filter

**Ceramic filters** play a crucial role in the foundry industry. These filters are used to prevent the infiltration of impurities such as inclusions, slag, and oxides in molten metals. These impurities can affect the final quality of the cast parts, reducing their strength and causing surface defects.

**Advantages of Using Ceramic Filters**:

1. **Reduction of Impurities**: Ceramic filters effectively prevent impurities in molten metals, thereby improving the final quality of the cast parts.

2. **Improved Quality**: By eliminating impurities, the overall quality of cast parts is enhanced, reducing defects and surface blemishes.

3. **Mold Cleanliness**: Ceramic filters help in reducing mold contamination and preventing mold degradation.

4. **Lower Production Costs**: By minimizing defects and rejects, production costs are reduced, and efficiency is increased.

5. **Better Heat Distribution**: Ceramic filters help in even heat distribution within the molds, leading to improved final quality of the cast parts.

6. **Increased Strength and Durability**: Cast parts produced using ceramic filters have greater strength and durability.

These features and extensive applications make ceramic filters a vital and effective component in the foundry industry, playing a key role in improving the quality and efficiency of casting processes.