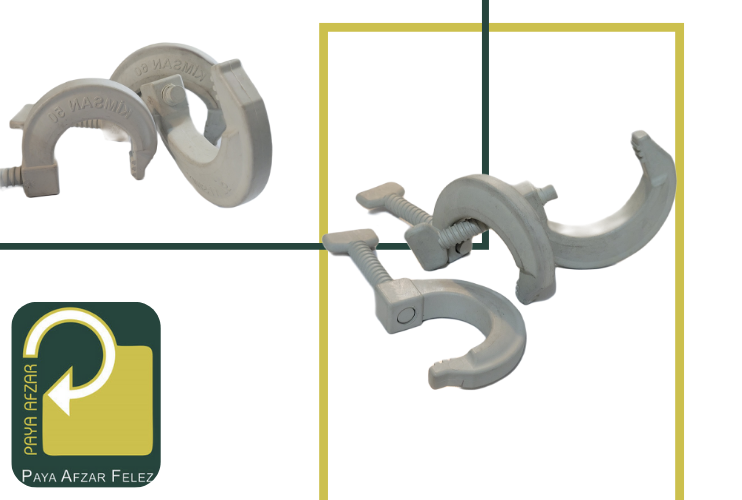

Clamp

**Plating Clamps (Screw Type)**

Plating clamps, also known as screw-type clamps, are essential tools in the processes of plating and anodizing aluminum. These clamps are specifically designed to securely hold aluminum parts during plating and anodizing processes. The use of these clamps ensures proper electrical connection and precise holding of parts.

**Features and Benefits of Screw-Type Plating Clamps**:

1. **High-Quality Material**: These clamps are made from high-quality compressed plastic, which offers high resistance to corrosion.

2. **Secure Holding**: The screw-type design ensures that aluminum parts are held securely and safely during plating and anodizing processes.

3. **Proper Electrical Connection**: These clamps help in establishing the proper electrical connection necessary for executing electrochemical processes effectively.

4. **Wide Applications**: These clamps are used in various industries such as electronics manufacturing, automotive, aerospace, and other aluminum-dependent industries.

These outstanding features and benefits make screw-type plating clamps an essential and efficient tool in the processes of plating and anodizing aluminum.