klevo glass

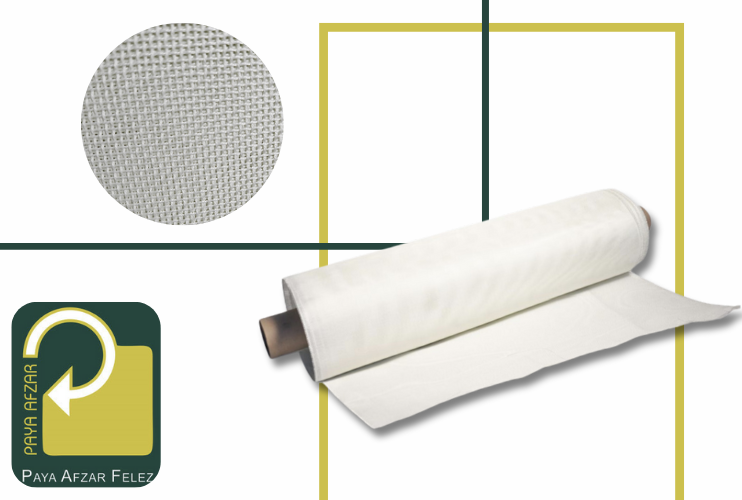

Fire-Resistant Mesh is a crucial product in the foundry industry, highly valued for its outstanding resistance to high temperatures. Crafted from special materials, it maintains its shape and integrity even under extreme heat, making it ideal for use in high-stress, high-temperature environments.

This mesh not only helps maintain the quality and consistency of casting materials but also enhances safety by reducing the risks associated with high temperatures in industrial processes. Produced under the reputable German brand KLEVERS, it stands as a testament to superior quality and excellent performance in its field.

**Fire-Resistant Mesh** has a wide range of applications in the foundry industry due to its unique properties and high resistance to heat. This product plays a crucial role in various casting processes. Some of the main applications are:

1. **Mold Protection:** Fire-Resistant Mesh is used as a protective layer in casting molds to prevent direct contact between molten metals and the mold walls, thus increasing the lifespan of the molds.

2. **Temperature Stabilization:** It helps maintain uniform temperature within the molds, preventing sudden temperature fluctuations that could negatively impact the final quality of the products.

3. **Thermal Insulation:** The mesh acts as a thermal insulator in high-temperature environments, reducing heat loss and enhancing the efficiency of casting processes.

4. **Reducing Thermal Stress:** By using Fire-Resistant Mesh, thermal stresses in casting components are minimized, leading to improved quality and reducing cracks and surface defects in the final products.

5. **Enhancing Safety:** The mesh helps reduce the risks associated with high temperatures in industrial settings, thereby increasing the safety of workers and equipment.

These features and applications make Fire-Resistant Mesh a vital and effective component in the foundry industry, playing a key role in improving the quality and efficiency of casting processes.