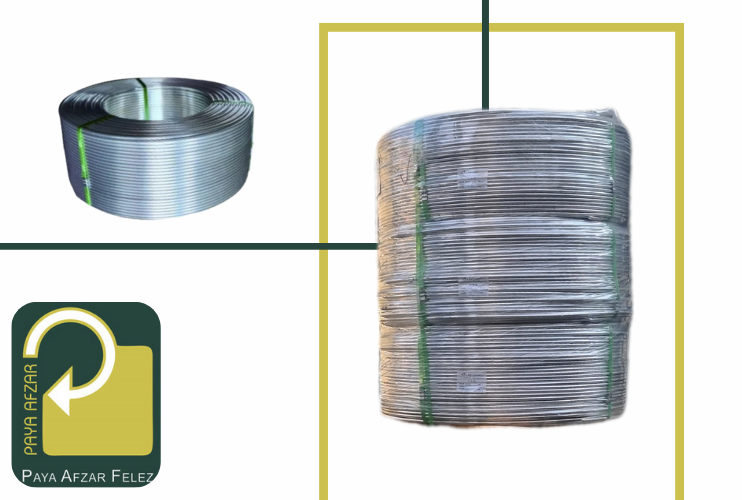

Aluminum Titanium Boron Rod

**Al-Ti-B Master Alloys** are widely used in the aluminum casting industry for grain refinement. The most common composition is **Al-5Ti-1B**, which provides about 100 ppm of titanium (Ti) and 20 ppm of boron (B) in the final castings. These alloys work by introducing **TiB₂** and **Al₃Ti** particles into the aluminum melt, which act as nucleation sites for the formation of fine α-Al grains during solidification.

The addition of Al-Ti-B master alloys helps achieve a uniform grain structure, which improves the mechanical properties and reduces the likelihood of hot cracking and other defects in the cast products. This grain refinement process is essential for producing high-quality aluminum castings with improved strength, ductility, and resistance to wear and corrosion.